ICP-OES is used in many fields: R&D, Quality Control and Quality Assurance, Analytical Service etc. The main market remains Analytical Service and QC/QA for production control of intermediate and final products. The domains of applications addressed by an ICP-OES vary significantly according to the design of the instrument and its performance.

The main application is environment (water, soils, sludges, air…) as there is a strong need to monitor element presence and content as it relates to human consumption and impact. For QA/QC, main customers are chemical, mining, precious metals and metallurgical companies. ICP-OES is used to guarantee the quality of raw materials as well as final product. Intermediate products are also analyzed so processes can be fully monitored. Petrochemistry uses also ICP-OES, for petroleum refining and lubricant oil production, but also for some applications such as wear metals in oil analysis that allow preventive maintenance to be done for engines (mining trucks, airplanes etc.).

ICP-OES can handle environmental and agro-chemical samples. The environment field is probably the main field of activity of ICP-OES. This is due to the wide variety of samples concerned, and also to the high and increasing demand for elemental analysis worldwide. ICP-OES became the reference technique for environmental analysis due to the demand for sensitivity along with multiple element analysis.

Environmental samples not only include analysis of samples from “natural areas” that include water (drinking water, underground water, sea water, river water…) to soils and sludges but it also includes analysis of workplaces with samples such as air, fly ash, coal ash or dust analysis. There are multiple requirements for an ICP-OES to meet expectations for environmental analysis. The ICP-OES should allow analysis of major elements at mg/L to % level. It should also be sensitive enough for the determination of low level of heavy metals in samples such as drinking water, underground water or river water, and exhibit reduced matrix effects so the sensitivity remains good in more difficult matrices such as sea water, waste water, soils or sludges. For these last samples, High Total Dissolved Solids tolerance is also a requirement to provide adequate stability.

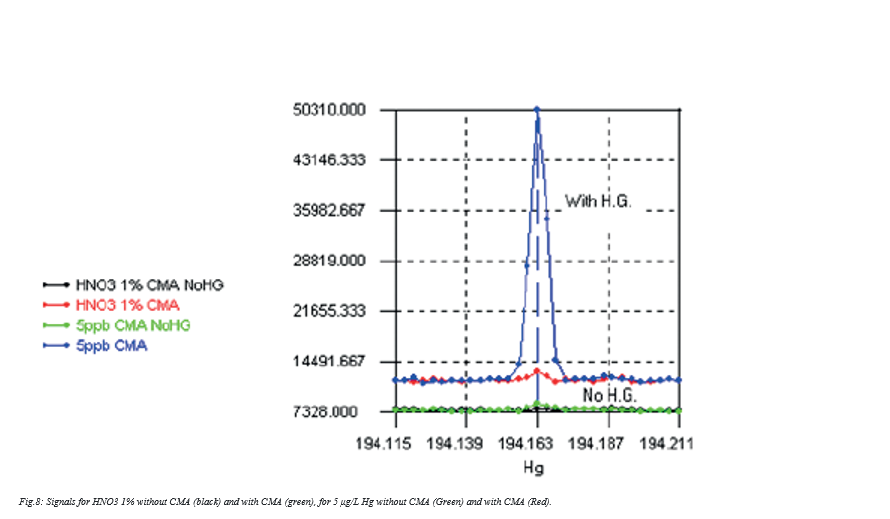

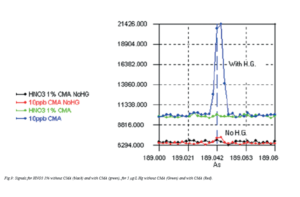

As the level of concentration defined by regulations is sometimes reaching the limits of the technique for some elements such as As, Se, Sb and Hg, some accessories can be used to improve sensitivity. HORIBA Scientific can propose the Concomitant Metals Analyzer (CMA) that uses the hydride generation technique to improve sensitivity for As, Se, Sb and Hg. The CMA can be used as a classical hydride generator but its uniqueness is that it can simultaneously analyze hydride forming elements and other elements, resulting in improved throughput and ease-of-use.

ICP-OES can handle chemical samples. Analysis of chemicals is mainly done in a production quality control context with analysis of intermediate and finished products, but also to monitor processes. Elemental analysis in such a context is mainly done using ICP-OES due to its multiple element analysis capability and its short analysis time that meets the requirement for production.

There are numerous matrices for chemicals analysis covering the wide range of the chemicals industry. Among these applications, we can include fertilizers, with a high focus on P and K analysis, batteries, with a focus on the analysis of Pb, Mn or Li, polymers and raw inorganic products. Analysis of organic solvents can also be done in such applications.

One of the most demanding industries in terms of ICP-OES performance is the chlorine, caustic soda, soda ash, sodium and magnesium production industry. For such industries, analysis of brines, that is a saturated NaCl solution (25 to 30% NaCl), is required. To get the best performance for such samples, it is mandatory to use an ICP-OES able to handle a total dissolved solids concentration, and one able to maintain sensitivity for trace elements analysis. Accessories such as a sheath gas and argon humidifier will be required to meet requirements for analysis.

ICP-OES can manage metallurgical samples for ferrous, nonferrous and precious metals. Metallurgy is one of the oldest application fields with geology.

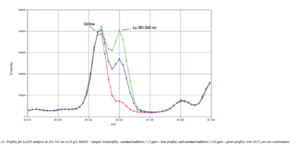

Multiple elements should be analyzed from trace level (ppm in the solid) to the high % range. ICP-OES is designed to handle such analysis and to give a result in a short time for all elements, making it the ideal instrument for this industry. High Resolution ICP-OES is preferred to allow for trace analysis due to the line-rich spectra emitted by all metals at high concentration such as W, Fe, Pt, Rh, Ni, etc.

ICP-OES can manage pharmaceutical and cosmetics samples. ICP-OES is well adapted for the analysis of heavy metals in cosmetic or pharmaceutical products, as most of them can be digested with acids or dissolved in volatile solvents such as methanol or ethanol. As volatile solvents can be introduced in the ICP-OES, it simplifies the sample preparation, and as more and more elements have to be analyzed on cosmetics, ICP-OES is more and more attractive.

Pharmaceutical products analysis should usually follow FDA regulations and ICP-OES had recently been authorized. This is an increasing application field as most of the companies will have to equip their laboratories to adhere to regulations. As for cosmetics, samples can be digested or directly dissolved in volatile solvents. For pharmaceutical products analysis, specific software meeting requirements from 21 CFR Part 11, and most of the time with user’s rights management is mandatory. Besides cosmetic and pharmaceutical applications, the use of ICP-OES can be extended to some clinical applications.

ICP-OES can handle geological, mining and rare earth elements. ICP-OES is widely used in mining processes, mining purity control, rocks analysis, etc. Many mines use ICP-OES to check for the purity of the extracted ores of manganese, nickel or precious metals. As mining resources decrease, there is also a huge activity to mine scrap metals and mainly precious metals from electronic wastes.

For this activity, ICPOES is used to evaluate the amount of metal that can be scrapped from the waste then to evaluate the purity once refined. Actually, ICP-OES is widely used for Rare Earth Elements analysis as the control of such elements becomes more and more important due to the crucial role of Rare Earth Elements in the economy, from daily life to advanced R&D.

ICP-OES can manage samples from materials sciences. ICP-OES is well designed for the analysis of samples from materials sciences and it is widely used for cements, ceramics or glass analysis due to its capability to analyze both major and trace elements simultaneously, with a good sensitivity.

As the use of magnetic materials becomes more and more important, ICP-OES is increasingly used for such applications, as it is designed to determine major and trace elements. For applications involving Rare Earth Elements, high resolution is often required to ensure quality of results.

ICP-OES can manage all kinds of samples for nuclear energy applications. Elemental analysis for nuclear energy applications is done in many fields: environment, metallurgy, geology and mining, nuclear plant monitoring, nuclear waste management, nuclear fuel analysis… For all active samples, special adaptation of the ICP-OES should be done with a glove-box to protect people and isolate the sample. As soon as analysis is done for metallurgical samples or on nuclear fuel related samples, high resolution ICP-OES spectrometers are required due to the line-rich spectra emitted by the elements of the matrices.

ICP-OES can manage petrochemical samples. ICP-OES is able to analyze directly organic solvents, simplifying analysis of petrochemical samples as most of them can be dissolved directly in solvents such as kerosene, xylene, or volatile solvents such as methanol, ethanol. Applications for ICP-OES can be found in refineries for crude oil analysis and also analysis of finished products such as bitumen or fuel.

Analysis of additive elements in lubricating oils can also be managed easily by ICP-OES, as well as the analysis of wear metals in oil which is very similar. Analysis of wear metals in oils is usually performed for plane or helicopter engines to plan for preventive maintenance.